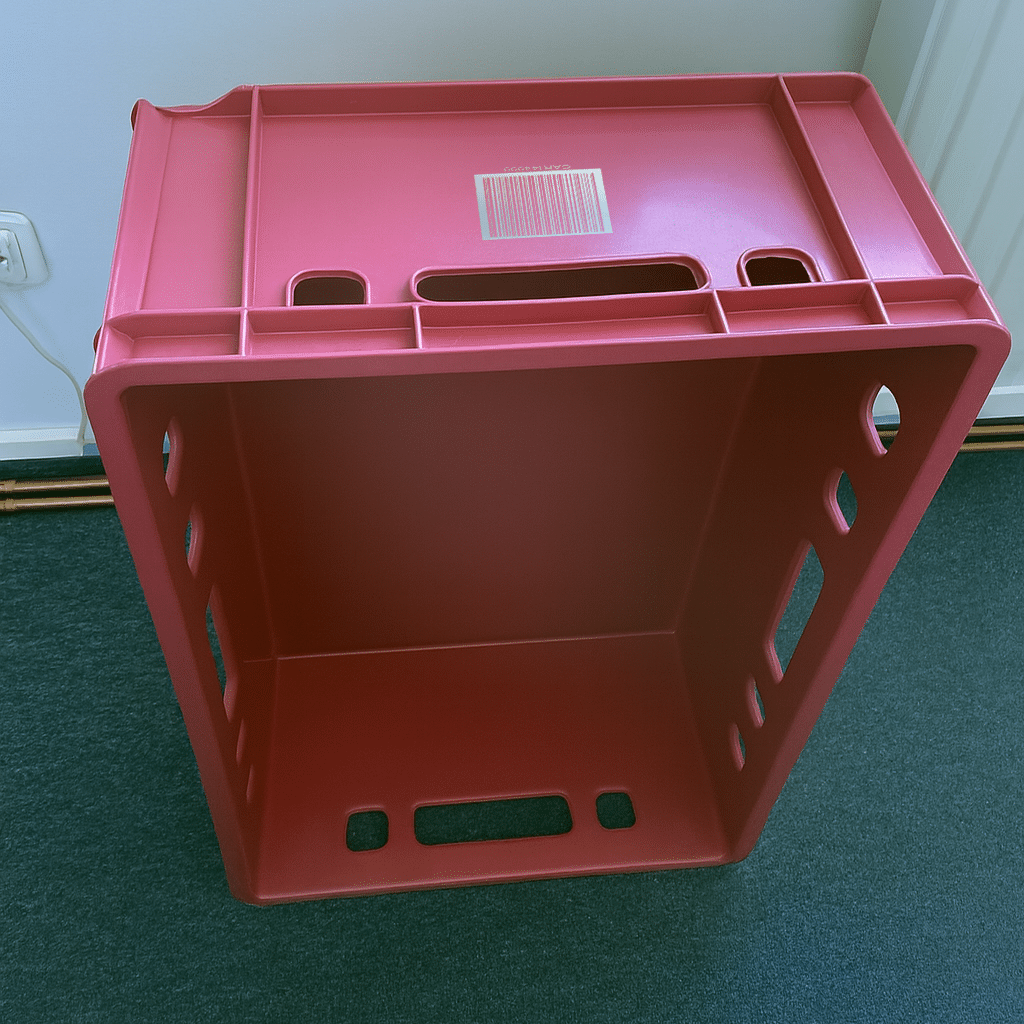

Whether in the logistics sector or the industrial sector, the permanent and resistant marking of reusable containers is an essential requirement to ensure traceability, regulatory compliance, and the optimization of logistics flows.

Direct marking of reusable packaging and returnable containers ensures that the identification remains resistant to industrial washing, friction, and chemicals, while staying readable throughout the lifecycle of the container.

In certain industries such as the food sector, durable marking of reusable containers is required to ensure the traceability of reuse and to meet transparency obligations regarding the flow of returnable packaging.

Beyond compliance, the marking of reusable containers enables the automation of logistics flows, optimal inventory management, and loss reduction through unique and unit-based traceability.

Furthermore, direct part marking (DPM) meets all durability, readability, and traceability requirements set by the AGEC law and ISO 17367 / ISO 28219 standards.

The choice of permanent marking technology for reusable containers is based on a life-cycle cost analysis: initial equipment cost, marking/reading cost, marking longevity over the number of reuse cycles, and the type of material to be marked.

In an agri-food environment, high-definition laser marking or green laser marking offers a consumable-free and hygienic solution, while in the transport and industrial logistics sectors, dot peen marking ensures readability even after multiple industrial wash cycles and mechanical handling.

Depending on technical and economic criteria, SIC MARKING offers various standalone or integrated marking machines to provide durable marking solutions for reusable containers.

Direct marking addresses the major challenges of traceability for reusable containers by providing a permanent and tamper-proof mark, unit identification, and detailed lifecycle tracking, which helps reduce losses, optimize reuse, and ensure regulatory compliance.

Direct marking of reusable containers in the industry ensures permanent identification of containers, guaranteeing durability, unit-level traceability, and quality compliance in demanding environments.

Reusable containers, which represent a major logistics asset, undergo intensive cycles of handling, storage, and washing, requiring permanent identification to ensure continuous flows, inventory visibility, and reduced costs from losses or replacements.

Laser marking and dot peen marking address distinct needs: laser marking prioritizes speed and precision for technical plastics and lightweight parts, while dot peen marking provides superior mechanical durability on metals and surfaces under heavy stress.

For mixed fleets (PP bins, steel crates, metal pallets…), manufacturers often adopt a hybrid approach — laser marking for bins and trays, dot peen marking for structural elements.

Direct marking of reusable containers has become a strategic solution to ensure permanent identification, reliable traceability, and seamless integration with ERP/WMS systems, enabling logistics and transport to reduce losses, improve operational efficiency, and enhance regulatory compliance.

Automatic reading of markings with fixed scanners, mobile devices, and vision systems allows faster sorting and picking operations: flows can reach several thousand reads per hour depending on the setup, which increases line productivity and reduces dock waiting times.

Laser marking provides fast, high-contrast, and aesthetic marking, while dot peen marking ensures deep and robust identification.

In the food industry, direct marking via laser engraving or dot peen marking on reusable containers addresses traceability, hygiene, durability, and compliance requirements.

Direct marking using fiber laser engraving, green laser, or dot peen provides significantly better durability than adhesive solutions or inkjet printing.

Readability is maintained even after several hundred industrial washing cycles, and the marking withstands alkaline detergents and high temperatures.

Engraving without added material reduces contamination risks from adhesives or inks: laser engraving creates a smooth surface that does not easily retain food residues or biofilms, supporting cleaning procedures and HACCP compliance.

Direct marking is compatible with indirect food contact and facilitates traceability of cleaning and maintenance operations required by ISO 22000 and BRC standards.

Contact Us

Need information?